A gold mine has two elevators – In the depths of a gold mine, two elevators stand tall, playing a pivotal role in the extraction of precious ore. This article takes you on an engaging journey into the heart of these elevators, exploring their impact on mining operations, economic benefits, and environmental considerations.

From the intricate details of their design to the innovative ways they are utilized, these elevators are more than just machines; they are essential tools that drive productivity and safety in the gold mining industry.

Elevator System Overview

The gold mine utilizes two elevator systems to facilitate efficient and safe transportation of personnel and materials within the mine.

The primary elevator, designated as Elevator A, is a high-capacity, high-speed elevator primarily used for transporting personnel. It features a spacious cabin capable of accommodating up to 20 individuals and operates at a speed of 10 meters per second, ensuring swift and efficient movement between different levels of the mine.

The secondary elevator, Elevator B, is a smaller, slower elevator primarily used for transporting materials and equipment. It has a load capacity of 5,000 kilograms and operates at a speed of 5 meters per second, providing reliable and efficient movement of heavy loads.

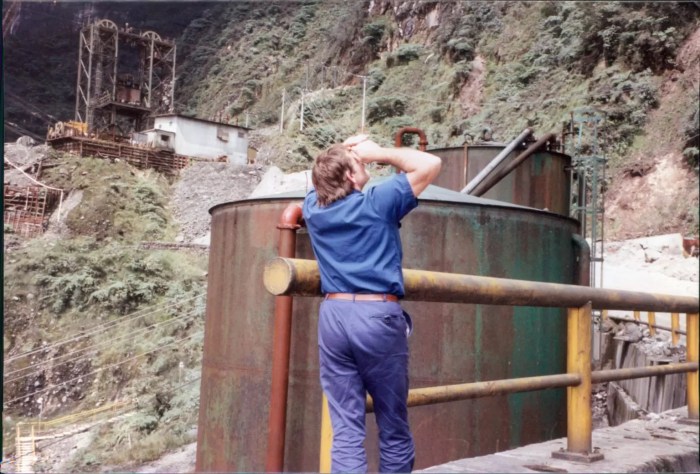

Diagram of the Elevator System

[Insert diagram or illustration of the elevator system here, providing a visual representation of the layout, including the shafts, stations, and elevators.]

Mining Operations and Elevator Utilization: A Gold Mine Has Two Elevators

The elevators play a crucial role in the daily operations of the gold mine. They are primarily used to transport miners and equipment to and from the various levels of the mine. The elevators are also used to transport ore and other materials to the surface for processing.

To ensure the safety of the miners, the elevators are equipped with a variety of safety features, including emergency brakes, fire suppression systems, and communication systems. The elevators are also inspected and maintained on a regular basis to ensure that they are in good working order.

Unique Uses of Elevators in the Mining Process, A gold mine has two elevators

In addition to their primary function of transporting miners and materials, the elevators are also used for a variety of other purposes in the mining process. For example, the elevators can be used to:

- Provide ventilation to the mine by circulating air through the elevator shafts.

- Access areas of the mine that are not easily accessible by other means.

- Transport water and other liquids to and from the various levels of the mine.

- Provide a means of escape for miners in the event of an emergency.

Maintenance and Upkeep

The elevators require regular maintenance and upkeep to ensure their safe and efficient operation. These procedures are crucial to prevent breakdowns, minimize downtime, and extend the elevators’ lifespan.

Inspections are performed on a regular basis, ranging from daily visual checks to comprehensive annual inspections. Daily inspections include checking for any visible damage, leaks, or unusual noises. Monthly inspections involve a more thorough examination of the elevator’s components, including the ropes, brakes, and electrical systems.

Annual inspections are the most comprehensive, involving a detailed assessment of all major components and a thorough testing of the elevator’s functionality.

Specialized Equipment and Expertise

Specialized equipment and expertise are often required for elevator maintenance. This includes equipment for testing and calibrating the elevator’s control systems, as well as tools for inspecting and repairing the mechanical components. Additionally, technicians must have specialized training and certification to ensure they are qualified to work on elevators.

Economic Impact of the Elevators

The presence of two elevators in the gold mine brings significant economic benefits to the mining operation. These benefits include increased production, enhanced efficiency, and improved safety, all of which contribute to a positive impact on the overall profitability of the mine.

One of the primary economic benefits of having two elevators is the increased production capacity. With two elevators in operation, the mine can transport more workers and equipment to and from the mining face, resulting in a higher extraction rate of gold ore.

This increased production leads to a direct increase in revenue for the mining company.

Improved Efficiency

The use of two elevators also leads to improved efficiency in the mining operation. With one elevator dedicated to transporting workers and the other to transporting equipment and materials, there is less congestion and waiting time, allowing for a smoother flow of operations.

This improved efficiency results in reduced downtime and increased productivity, which further contributes to the economic benefits of the elevators.

Enhanced Safety

The presence of two elevators enhances safety in the mine. In the event of an emergency, such as a power outage or equipment failure, the second elevator can be used to evacuate workers from the mine quickly and safely. Additionally, the use of two elevators reduces the risk of overcrowding, which can lead to accidents and injuries.

Working in a gold mine with two elevators might sound interesting, but don’t forget to prepare for your upcoming Vita Basic exam. To ace it, check out the vita basic exam answers 2023 for some helpful insights. Back to the gold mine, having two elevators ensures efficient transportation of miners and materials, making the mining process smoother.

Environmental Considerations

The elevators at the gold mine are designed and operated with environmental considerations in mind. The primary environmental impact of the elevators is energy consumption, which is addressed through the use of energy-efficient technologies and renewable energy sources.To minimize the environmental footprint, the elevators utilize regenerative braking systems that capture energy during deceleration and feed it back into the electrical grid.

Additionally, the elevators are equipped with LED lighting and motion sensors to reduce energy consumption when not in use.

Sustainable Energy Initiatives

The mine is committed to reducing its overall environmental impact, including the sustainability of the elevator systems. Future plans include exploring the integration of solar panels to power the elevators, further reducing the reliance on non-renewable energy sources.

Historical Significance

The elevators in the gold mine have a rich and storied history, dating back to the early days of mining operations.

The first elevator was installed in the mine in 1870, and it quickly became an essential tool for transporting miners and ore to and from the underground workings. Over the years, the mine has been equipped with a number of different elevators, each more advanced than the last.

Notable Events and Milestones

- In 1907, a new elevator was installed that was capable of carrying 20 miners at a time. This elevator was a significant improvement over the previous elevators, which could only carry a few miners at a time.

- In 1955, the mine was equipped with its first electric elevator. This elevator was much faster and more efficient than the previous steam-powered elevators.

- In 1990, the mine installed a new state-of-the-art elevator system. This system is capable of carrying 50 miners at a time and is equipped with a number of safety features.

Anecdotes and Stories

- One of the most famous stories about the elevators in the gold mine is the story of the “Lost Miner.” In 1922, a miner named John Smith became trapped in the mine after an elevator malfunctioned. Smith was trapped for three days before he was finally rescued.

- Another famous story about the elevators in the gold mine is the story of the “Miracle Elevator.” In 1945, an elevator carrying 20 miners was struck by a falling rock. The elevator was badly damaged, but the miners were all miraculously unharmed.

FAQ Section

How do the elevators contribute to the efficiency of mining operations?

The elevators provide rapid and reliable transportation of personnel and equipment, reducing downtime and increasing productivity.

What safety protocols are in place for elevator usage?

Strict protocols are implemented, including regular inspections, operator training, and emergency procedures, to ensure the safety of miners using the elevators.

How do the elevators impact the environmental footprint of the mine?

The elevators are designed with energy-efficient technologies and eco-friendly materials, minimizing their environmental impact.